KARACHI, June 1: The Karachi Milk Plant’s fate seems to be sealed after the Sindh government handed over an eight-acre plot to the Board of Revenue and started mulling auction of its machinery, though experts related to the livestock sector still question the rationale behind the closure of the plant in view of milk shortages and the commodity’s escalating prices.

KARACHI, June 1: The Karachi Milk Plant’s fate seems to be sealed after the Sindh government handed over an eight-acre plot to the Board of Revenue and started mulling auction of its machinery, though experts related to the livestock sector still question the rationale behind the closure of the plant in view of milk shortages and the commodity’s escalating prices.

They say that consumers’ woes both in urban and rural areas over milk shortages and its rising prices will be overcome if the government rehabilitates the abandoned processing plants, around six to eight milk plants in Sindh, and set up chilling centres.

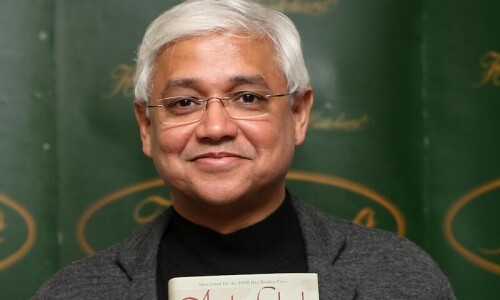

“The abandoned plants need to be rehabilitated and upgraded by using new technologies as well as the old ones, like the ‘reconstitution/toning of milk’, an old viable method introduced after the World War II, to meet the growing demand of milk and control its prices. There is no reason why the common man be deprived of milk in a country that stands as the third largest milk producing country. By all international standards, our cattle breeds are the best in the world,” says Dr Akbar Arain, who has recently retired from the department of animal product technology, Sindh Agriculture University, Tando Jam.

According to him, it is only because of the lack of interest, proper planning and failure of the government to check the monopoly of the private sector that today urban and rural consumers in Sindh find it hard to get milk at affordable rates.

At present, only three per cent of the 33 million ton milk produced annually in the country is processed.

The wastage stands at 15 to 20 per cent due of lack of storage facilities and processing units.

Twenty-four milk plants were established during General Zia-ul-Haq’s period. Of them four still exist. With the active participation of private companies during the recent years though the number of processing plants reached 11, it is basically the shortage of plants that compels the government to spend billions of rupees on the import of powdered milk and other dairy products every year. Last year, for instance, more than 27,000 tons of powdered milk was imported at a cost of Rs1.99 billion.

Chain of supplies

About the revival of the Karachi Milk Plant, Dr Arain says it can still be made operational if the government invests in establishing the required chain for milk supplies.

He says: “The revival of Karachi Milk Plant is the solution to the escalating prices of milk in the city. The project failed to take off because the government didn’t carry out a baseline survey. No effort was made to establish a chain of milk supplies and a collection unit. Some veterinary officers were asked to arrange milk supplies, but as a temporary arrangement. The government neither linked nor developed a dairy farm to meet the shortages. Not even the method of ‘reconstitution of milk’ in processing was adopted to cut losses and help reduce milk prices.

“After the government declared the Karachi Milk Plant non-viable in 2005, two milk plants were set up – one of them on the Super Highway in Karachi and the other in Sukkur – by the private sector. Both the plants are still operational. If the private sector can do it, why can’t the government?” asks Dr Arain.

‘Fresh’ milk

Explaining the method of reconstitution of milk, Jamil Memon, a dairy farmer, claims that it is widely used by private companies. Consumers are fleeced as powdered milk is basically liquidized and then sold in the name of fresh milk by some private companies.

“Milk is in short supply and will remain so since no infrastructure exists to support dairy farmers and increase animal productivity at the grass-root level. In the absence of any government checks on milk’s quality and prices, what these companies do is to make a preparation from powdered milk, add water and 3.5 per cent fat ingredients to meet shortages in milk supplies, which is later sold as ‘fresh milk’ on inflated rate,” the farmer says.

Dr Arain argues that the process is very much legal under the Pure Food Laws, 1967, which state that ultra heated, treated milk must contain 3.5 per cent animal fat derived from milk sources and 8.9pc other solid contents minus fat. However, he says the high price being charged on account of ‘reconstituted milk’ is unfair.

He further says: “The major quantity of buffalo milk, containing six to eight per cent fat, is used in making tea in the country. This is a huge waste of milk resources. If fat is separated with the help of milk separators and used in making various other dairy products as is being done in India, this can reduce milk prices and the country can also earn precious foreign exchange,” he adds.

The story of KMP

Established at a cost of Rs6.785 million in 1965, the Karachi Milk Plant was supported by the Unicef, Food and Agriculture Organisation of the United Nations and the Government of New Zealand. It had a pasteurization capacity of 25,000 litres with a total dairy produce of 75,000 litres.

The plant received foreign assistance of Rs18.252 million from 1965 to 1979 and ran for 15 years before it came to a halt on January 10, 1980, when the government declared its performance as non-satisfactory.

In 2002, the Sindh government worked out a joint venture with Idara-i-Kissan, an NGO successfully running two milk plants and supporting dairy households in over 1,000 villages in Punjab, for KMP’s revival under the Indus Dairy Development Project. The approved estimated cost was Rs50 million of which the government undertook to invest Rs40 million and the rest was pledged by the NGO.

The plant was allotted 36 acres out of which about 29 acres were encroached upon, while the remaining eight acres were occupied by different government departments and agencies, including Rangers, traffic/FIA courts, election commission office, and livestock and fisheries department. To relaunch the project, all the offices were removed from the eight-acre plot.

Ameen Bukhari, who heads the Idara-i-Kissan, admits that the failure to develop a chain of milk supplies and conduct a proper feasibility survey was the major reason behind the KMP’s failure.

“The baseline survey was carried out two years after it started its operation. By that time it was too late. We were constantly suffering losses due to severe shortages of milk. The target was to get 35,000 to 40,000 litres milk per day from the interior of Sindh, but we were hardly getting 2,000 litres,” he says citing acute poverty and lack of infrastructure for Sindh’s low milk production as compared to Punjab’s.

A visit to the site shows that the remaining piece of land is surrounded by flats and katchi abadis, most of them now regularised. Despite repeated attempts, Dawn’s team was not allowed by the officials concerned to go inside the abandoned plant and take pictures of the machinery that is still in working condition, according to sources.

Commenting on the Sindh government’s plans to auction the Rs5 million machinery, newly installed at the time of its revival in 2002, Dr Arain suggests that instead of selling it as scrap the government can make use of it by installing it in any other processing unit that it deems feasible for rehabilitation.

Dear visitor, the comments section is undergoing an overhaul and will return soon.