Building habitats and structures has been native to mankind since the onset of civilisation. Apart from shelter and security, structures have been erected to portray authority, commemorate love and advocate cultural heritage.

These structures were built from naturally occurring substances such as clay, sand, wood, rocks, twigs and even leaves. As time progressed, research and technology gradually improved construction practices with an equivalent transformation in building materials to address cost effectiveness, durability and eco-friendliness.

Whilst the advancement in building materials continues to flourish worldwide, the construction industry in Pakistan is still entrenched with conventional materials. However, there are some ingenious individuals who envisage a bright future in the area of construction materials.

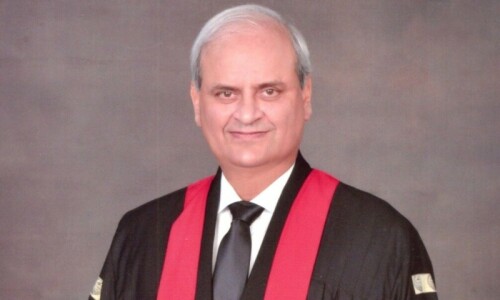

Hasan Akhtar is perhaps one of those innovators who are striving to produce hi-tech materials aimed at alleviating building difficulties. After graduation from the NED University he obtained his master’s degree in civil engineering from Cornell University, US. He started his career as a geo-environmental consultant initially in the US and later in Pakistan.

Taking cognizance of the fact that construction industry in Pakistan lags in technological developments; his persistent research in construction materials led him to identify numerous areas of innovation and application.

What products are you currently manufacturing and what are the benefits accrued?

At present, we are producing various lightweight concrete moulds made from cement, cellulose fibre derived from used newsprint and some advanced chemicals on machinery that has been indigenously developed. Reformulation results in lightweight blocks, panels and tiles having numerous advantages.

These blocks of recyclable material, given an equivalent function, weigh only 30 per cent of the conventional block. Benefits which these products provide, besides toughness, include thermal insulation, energy efficiency and seismic cures. Being light in weight it is beneficial particularly in case of high-rise buildings and has the added benefit of being fire resistant. What was the starting point of your success in eco-friendly materials?

The breakthrough became visible once I started regular participation in material exhibitions; meeting like-minded people who were willing to collaborate for research and manufacture of innovative products in Pakistan. Thereafter, having set achievable goals, I systematically organised the production techniques.

Do you comply with any building and quality standards, which serve as a testament to your processes and products?

We follow the ASTM standards and European EN standards. We are currently on the Technical Committee of Standards at Pakistan Standards and Quality Control Authority (PSQCA), where we are reviewing international standards and their relevant adoption and application in Pakistan.

Have you had any assistance from the government for your ventures?

Well, our government has limited resources and we do not expect financial assistance. We are fortunate in our case and are grateful for the initial assistance given to us by the Council for Works and Housing, a constituent of department of science and technology. The government can, however, facilitate the development of new indigenous materials by encouraging its engineering design department to try out what we have to offer.

What is the current market potential for the products that you manufacture?

There is a limited market for the time being as new products are not easily accepted. Stakeholders in the construction industry generally want to play safe and resort to conventional methods. The reason for this reluctance is the growing knowledge gap as the engineering community does not engage in progressive learning.

How important is it to bridge the knowledge gap under the prevailing academic scenario?

Knowledge is widely recognised as the most important factor of production in a developing economy. Though the meaning of knowledge is never clearly defined, but we can deduce that education, research and development along with information and communication technology infrastructure are the crucial variables. I would urge students and prospective inventors to make use of the information highway to hasten the reduction of the knowledge gap.

Do you see any new opportunities that you intend to venture into?

There is very little work that has been done to adopt technology for customised solutions. The challenge I confront is to join the dots and fill the gaps to formulate comprehensive projects. I am also investigating soil retaining fibrous products that can reduce soil erosion by about 90 per cent. My research is also aimed at materials that can prevent seaside salt spray ingestion into buildings and marine structures. I am also devising materials that retard crack propagation to prevent catastrophic failures.

Dear visitor, the comments section is undergoing an overhaul and will return soon.