Pakistan is the world’s 11th largest broiler chicken producer today. But that wasn’t always the case.

Half a century ago, chickens were ‘backyard poultry,’ grown mainly by villagers in small numbers around their homes and sold in the wet market. There was no commercial poultry production in the country at that time.

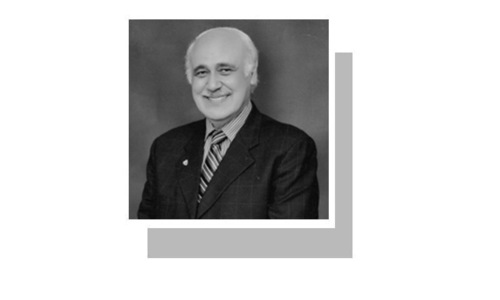

Khalil Sattar, the chairman of the K&N’s Group of Companies, who was a college student at that time, saw through this gap and recognised the huge business potential and profits in “moving chicken-farming from small-scale domestic production to industry-scale poultry production”.

His first flock of birds was raised in a spare shed at the family’s oil extraction factory in Karachi back in 1963. Soon he was supplying hand-processed chicken meat to a five-star hotel, Intercontinental. The relationship did not last long. But he had already expanded his broiler stock and undertaken advisory and extension services to help poultry farmers in rural Punjab increase their production.

When the 1971 war with India disrupted the supply of chicken feed, he went on to establish his own mill. In the mid-1970s, he moved into breeding. In the early 1980s, he expanded his breeding operations and set up the country’s first controlled environment house for broiler production.

This was followed by the acquisition of a processing plant in Lahore in 1996. Sattar made the purchase despite the fact that almost every previous attempt at making processing a profitable business had failed in the past.

The small-scale broiler farm he had started 50 years ago has now grown into the country’s largest vertically integrated poultry business, with operations ranging from the production of breeding stock to retail stores across major cities.

In 2012, K&N’s was selected by the Harvard Business School as a case study for its students because of the company’s business model and marketing practices

The group is engaged in feed-milling, grandparent and parent stock production, hatching, broiler production, and processing.

The company has more than half of the market share in the frozen and processed chicken meat products and has expanded its operations to the US by acquiring a processing plant in Syracuse, New York.

K&N’s has provided a model for the development of the domestic poultry industry. In 2012, it was selected by the Harvard Business School as a case study for its students because of its business model and marketing practices.

“We faced different challenges and problems, but always remained focused and honest to our objective of providing healthy chicken products to the people and create jobs in the country,” Sattar said in an interview with Dawn.

But he is not very happy with government policies, which, he says, are biased in favour of imports instead of domestic poultry production.

“Our policymakers formulate policies that encourage importers and punish producers. It is much easier to import value-added, processed chicken products than to export them. It is because of this reason that a local company has already shut down its production and now sells imported chicken products with its own label.”

He pointed out that the Free Trade Agreements (FTAs) that Pakistan had signed with countries like Malaysia and China had opened the domestic market to cheaper, duty-free imports of poultry products. “And you cannot export your products to these countries because our health and food safety regulations and standards are not compatible with theirs.”

Sattar said the Indian government had raised taxes on chicken imports to 100pc from 25pc when an American fast food chain had opened its outlets there. “When they protested, the Indian government told the firm to either buy chicken meat and value-added products from the local market or set up their own production facility there. Will anyone in Pakistan protect its industry in this manner? No.”

He added that apart from government policies that encourage imports, heavy taxes on the import of inputs — which constitute almost one quarter of the total manufacturing cost of processors — used in value-added poultry products, as well as energy shortages and the large unorganised poultry market in the country are other major issues slowing the growth of the processing industry.

And the present government has abolished zero-rating of local production and sales of poultry products in the organised sector.

“The heavily taxed producers of processed chicken products have to compete with the large wet and live chicken market and also with cheaper imported products. How can we achieve economies of scales? How do you expect anyone to survive in this environment?” he wondered, saying the unorganised poultry market contributes almost 96pc of total sales in the country.

Sattar added that when he went to the US to establish a processing plant, various counties offered him incentives to attract him. “Nobody asked me how much money I planned to invest; the only thing they wanted to know was how many jobs I will create. The county where I acquired the closed plant is paying half the salary of each former employee of the factory that I have reemployed. They know how important it is to create jobs. Why can’t our policymakers see this?”

Published in Dawn, Economic & Business, April 27th, 2015

On a mobile phone? Get the Dawn Mobile App: Apple Store | Google Play